How Do You Release Pressure From An Oxygen Tank? A Simple Guide

Quick Answer: To release pressure from an oxygen tank, turn the release valve counterclockwise gently after checking the pressure gauge, ensuring a controlled and safe pressure reduction.

Key Takeaways:

- Familiarize with the oxygen tank’s components, including the pressure gauge, regulator, and release valve, to safely monitor and control the release of pressurized oxygen, ensuring the gauge reads a safe level before and during the release process.

- Prioritize safety by wearing appropriate Personal Protective Equipment (PPE) such as gloves and eye protection, releasing pressure in a well-ventilated area, and removing any flammable materials or ignition sources from the vicinity to prevent fire hazards.

- Regular maintenance, including routine checks for leaks and valve integrity, professional servicing, and proper cleaning and storage, is essential to ensure the oxygen tank’s safe operation and longevity.

When you’re dealing with an oxygen tank, it’s like handling a bottle of champagne. You wouldn’t want the cork to pop off unexpectedly, right? The same goes for an oxygen tank; releasing the pressure is a delicate process that must be done with care and understanding. Before diving into the nitty-gritty, it’s crucial to grasp the fundamentals of the process. This ensures that you can handle the tank safely and efficiently.

First and foremost, familiarize yourself with the manufacturer guidelines and safety protocols. These are not just suggestions; they are the roadmap to preventing accidents. Each tank might have its own set of instructions, so it’s important to read these thoroughly before proceeding. Remember, safety is paramount when dealing with pressurized oxygen.

Releasing Pressure from an Oxygen Tank: The Basics

Understanding the Parts of an Oxygen Tank

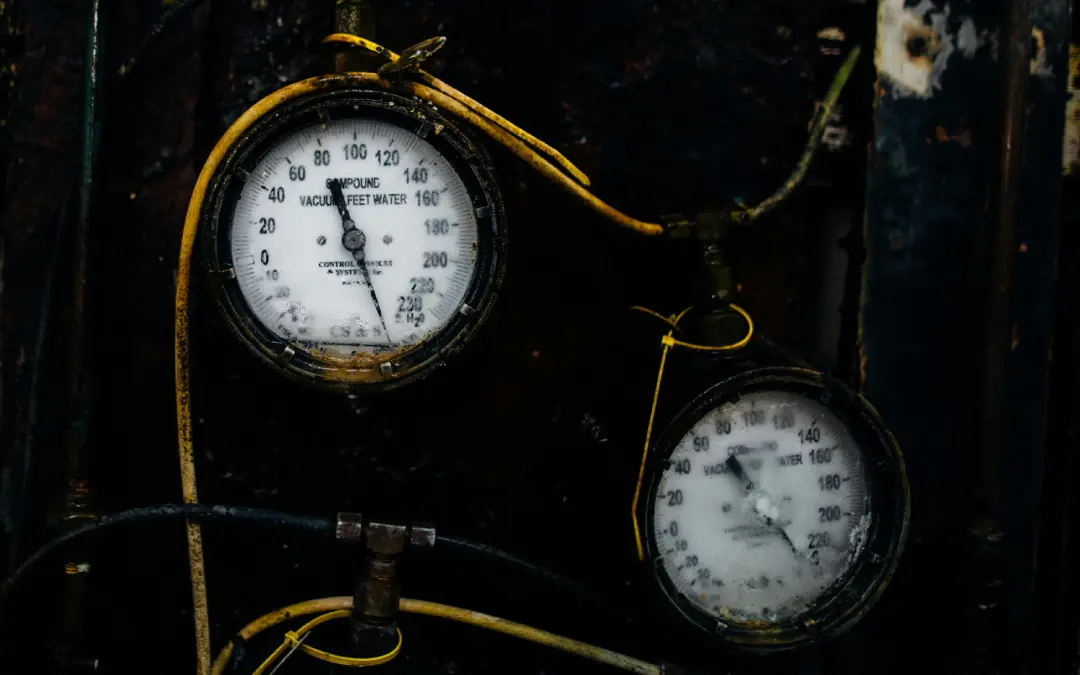

An oxygen tank is more than just a metal cylinder. It’s a sophisticated device with several key components that work together to store and release oxygen safely. The pressure gauge is your window into the tank’s soul, showing you exactly how much pressure is inside. It’s a dial that needs to be read correctly to avoid any mishaps.

Next, we have the regulator. Think of it as the manager of the oxygen flow, controlling how much oxygen is released. It’s a critical component that ensures the tank operates at a safe level and delivers oxygen at a rate that’s usable for the intended purpose.

Finally, the release valve is the gatekeeper. It’s the part you’ll interact with when you want to let some of that pressurized oxygen out of the tank. It’s essential to operate this valve correctly to maintain control over the pressure release.

Recognizing the Pressure Gauge and Release Valve

To safely release pressure from an oxygen tank, you need to be on good terms with the pressure gauge and release valve. The pressure gauge is your go-to tool for monitoring the tank’s internal pressure. It usually has a needle that points to numbers on a dial, indicating the pounds per square inch (PSI) inside the tank. A full tank typically reads around 2,000 PSI, but this can vary.

Now, let’s talk about the release valve. It’s not just a simple on-off switch; it requires a gentle touch. To operate it, you’ll often turn it counter-clockwise, but only after you’ve checked the pressure gauge. If the needle is in the green zone, you’re good to go. But if it’s in the red, that’s your cue to proceed with extra caution.

As you engage the release valve, listen for the hiss of escaping oxygen and watch the pressure gauge’s needle drop. This visual and auditory feedback will guide you in managing the pressure release. It’s a bit like letting air out of a balloon – too fast and you might startle everyone; too slow and it’ll take forever. Aim for a steady, controlled release until the gauge indicates that the tank is at a safe pressure level for handling.

Handling an oxygen tank requires a blend of knowledge and caution. By understanding the equipment and following the correct procedures, you can ensure a safe and successful pressure release. Always keep the core concept in mind: releasing pressure from an oxygen tank is about precision and safety.

Safety Precautions Before Releasing Pressure

Before you even think about touching that release valve, let’s talk safety measures. Handling an oxygen tank requires respect and caution. The risks of improper handling aren’t just a bad day—they can be catastrophic. So, a safety checklist is not just a suggestion; it’s a must. It’s like the pre-flight checklist a pilot runs through before takeoff. Every item is there to ensure the safety of everyone involved.

Personal Protective Equipment (PPE) for Handling Oxygen Tanks

When you’re about to release pressure from an oxygen tank, dressing for the occasion means more than just looking the part. Personal Protective Equipment (PPE) is your first line of defense against potential hazards. Here’s what you’ll need:

- Gloves: These aren’t just any gloves. You’ll want ones that can shield you from the cold that can come from the pressurized oxygen as well as provide a good grip.

- Eye protection: Safety glasses or face shields are non-negotiable. If something goes wrong, your eyes are vulnerable, and we want to keep them safe.

Each piece of safety gear is designed with a purpose. Gloves protect your hands not just from the cold, but also from any sharp edges or debris. Eye protection is there to guard against any unexpected sprays or particles. Don’t skimp on PPE—it’s a simple step that has a big impact on your safety.

Ensuring a Ventilated Area for Pressure Release

Oxygen is great for breathing, but in high concentrations, it’s a fire waiting to happen. That’s why you need to release pressure in a well-ventilated area. This isn’t just about comfort; it’s about preventing a fire hazard. Here’s what makes a spot ideal for this task:

- Open spaces are your friend. The more air flow, the better.

- Indoor areas should have fans or ventilation systems that can disperse the oxygen quickly.

The goal is to prevent oxygen accumulation, which can turn a small spark into a big problem. By choosing the right environment, you’re taking a big step towards a safe pressure release.

Checking for Potential Hazards

Before you start, take a moment to scan your surroundings. You’re looking for anything that could ignite—because where there’s oxygen, there’s a potential for fire. Here’s what to keep an eye out for:

- Flammable materials: Keep them far away from your work area. This includes oils, greases, and other combustibles.

- Ignition sources: This isn’t just about open flames. Electronics, static, even a spark from metal hitting the ground can be enough.

Once you’ve identified any risks, it’s time to secure the area:

- Remove any hazards from the vicinity.

- If you can’t remove it, find another spot to release the tank’s pressure.

By being thorough in your area inspection and risk minimization, you’re not just following best practices—you’re ensuring that you can release pressure from your oxygen tank without turning a safety procedure into an emergency.

Step-by-Step Guide to Releasing Pressure

Releasing pressure from an oxygen tank is a task that requires precision and care. Whether you’re a novice or have experience, following a step-by-step guide can help ensure the process is done safely and effectively. Different oxygen tank models may have specific instructions, so always refer to the manufacturer’s manual for details. Let’s walk through the general procedure.

How to Properly Position the Oxygen Tank

First things first, you need to position your tank correctly. This means:

- Placing the tank upright to ensure stability.

- Making sure the valve and gauge are easily accessible.

- Using any necessary tools and supports, like a tank stand or wall bracket, to secure the tank.

Proper positioning is crucial because it prevents the tank from tipping over and allows you to operate the valve and read the gauge without strain.

Detailed Instructions for Opening the Release Valve

Now, let’s focus on the release valve. Here’s how to open it safely:

- Identify the direction to turn the valve—typically, you’ll turn it counter-clockwise.

- Gently turn the valve to start releasing pressure. You should never force it.

- Be cautious not to over-loosen the valve, as this can lead to complications.

As you perform these steps, pay close attention to the pressure gauge. It should start to show a decrease in pressure as you open the valve.

Monitoring the Pressure Gauge During Release

Keeping an eye on the pressure gauge is not just important—it’s essential. Here’s why:

- It helps you avoid rapid decompression, which can be dangerous.

- It allows you to maintain control over the release process.

Watch the gauge closely and proceed slowly. If the needle drops too quickly, pause and let the pressure stabilize before continuing.

Steps to Take After Releasing Pressure

Once you’ve reached the desired pressure level, it’s time to wrap things up:

- Carefully close the valve by turning it clockwise until it’s snug.

- Check that the tank is secure and that there’s no sign of leakage.

- Record any necessary maintenance records or documentation.

After releasing pressure, it’s also a good idea to perform a quick post-release check of the equipment. Ensure everything is in order and the area is safe.

By following these steps, you can release pressure from an oxygen tank confidently and responsibly. Remember, safety is paramount, and patience is your ally in this process.

Troubleshooting Common Oxygen Tank Issues

Even with the best preparation, you might encounter some hiccups when releasing pressure from an oxygen tank. Don’t worry, though—most issues have straightforward solutions. Let’s walk through some common problems and how to tackle them without breaking a sweat.

What to Do if the Pressure Doesn’t Release

If you’ve turned the release valve and nothing’s happening, here’s what to do:

- Check for any obstructions in the valve or outlet. Sometimes, debris can block the flow.

- Make sure the valve isn’t frozen. If it’s cold to the touch, gently warm it up.

- If you suspect a malfunction, it’s time to seek professional assistance. Don’t try to force the valve if it seems to be a mechanical issue.

Remember, if the pressure isn’t releasing as it should, it’s better to err on the side of caution and get help from someone with experience.

Handling a Stuck Valve Safely

A stuck valve can be frustrating, but here’s how to approach it:

- Use appropriate tools like a valve wrench to gently apply more leverage.

- Avoid using excessive force. If it won’t budge, forcing it could cause damage or injury.

- Apply penetrating oil to help loosen the valve, but be mindful of flammability and oxygen compatibility.

The key is to be patient and gentle. If the valve still won’t turn, it’s time to call in the experts.

Dealing with Over-Pressurization

An over-pressurized tank is a serious concern. Here’s how to handle it:

- First, stop any oxygen flow into the tank immediately.

- Begin releasing pressure slowly, if possible, while monitoring the pressure gauge.

- If standard procedures don’t work, you may need to implement emergency measures, such as activating a safety device or calling for professional help.

Signs of over-pressurization include a rapidly climbing pressure gauge or a hissing sound from the safety valve. If you notice these, act quickly but calmly to resolve the issue.

By understanding these troubleshooting tips, you’ll be well-equipped to manage any minor issues that come up during the pressure release process. Stay calm, follow these guidelines, and remember that safety is always the top priority.

Oxygen Tank Maintenance and Care

To ensure your oxygen tank operates safely and effectively, regular maintenance and proper care are non-negotiable. Just like any high-functioning equipment, an oxygen tank requires a keen eye and a schedule for routine checks and professional servicing. Let’s delve into the practices that will keep your tank in top shape.

Routine Checks and Maintenance for Oxygen Tanks

Consistent inspections and maintenance tasks are the backbone of oxygen tank care. Here’s what you should regularly do:

- Conduct leak checks to ensure there’s no oxygen escaping from the tank.

- Verify valve integrity; a well-functioning valve is critical for safe operation.

- Check the pressure gauge for accuracy; an incorrect reading can be dangerous.

These maintenance steps play a crucial role in preventing issues when it’s time to release pressure. A well-maintained tank is a safer tank.

When to Service or Replace Your Oxygen Tank

Oxygen tanks are sturdy, but they don’t last forever. Be on the lookout for these signs that it’s time for servicing or replacement:

- Dents, rust, or other visible damage to the tank

- A valve that’s difficult to operate

- Inconsistent pressure readings

As for professional inspection, here’s a good rule of thumb:

- Have your tank inspected by a professional at least once a year.

- Service the tank immediately if any issues arise during your routine checks.

Staying on top of servicing will extend your tank’s lifespan and ensure it’s always ready for use.

Cleaning and Storing Oxygen Tanks Properly

Proper cleaning and storage are just as important as the checks and servicing. Follow these best practices:

- Store tanks in a cool, dry place away from direct sunlight and heat sources.

- Use only recommended cleaning agents to avoid chemical reactions with the tank material.

- Ensure the storage area is free of any materials that could ignite in high oxygen environments.

Avoid these common storage mistakes:

- Don’t store tanks in a car trunk or a hot, enclosed space.

- Keep tanks upright and secure to prevent them from falling over.

- Never store tanks with the valve open, even if the tank is empty.

By adhering to these guidelines, you’ll keep your oxygen tank in safe working order, ready to perform when you need it to release pressure or provide life-sustaining oxygen. Remember, a little care goes a long way in maintaining the reliability and safety of your equipment.

Emergency Procedures and First Aid

In the rare event of an oxygen tank malfunction or accident during pressure release, it’s vital to have a plan. Knowing the right emergency procedures and first aid techniques can make all the difference. Let’s walk through what to do to keep everyone safe.

Immediate Actions if an Oxygen Tank Leak Occurs

If you suspect your oxygen tank is leaking, act swiftly and follow these steps:

- Evacuate the area immediately to ensure everyone’s safety.

- Ventilate the space if possible to disperse the oxygen and reduce the risk of fire.

- Notify emergency services right away. They are trained to handle such situations safely.

It’s crucial to understand that oxygen tank repairs should only be performed by individuals with proper training. Attempting to fix a leak on your own could lead to further danger.

First Aid for Oxygen-Related Incidents

Accidents involving oxygen tanks can result in a range of injuries. Here’s how to address some common ones:

- For inhalation injuries, move to fresh air immediately and monitor for breathing difficulties.

- In the case of burns, cool the area with running water and cover with a clean, dry cloth.

Always err on the side of caution and seek medical attention if there’s any doubt about the severity of the injury. Remember, your well-being is the top priority.

Professional Resources and Support

Navigating the complexities of oxygen tank management can be challenging, but you don’t have to go it alone. There are numerous resources and forms of support available, from professional help to training opportunities. Whether you’re a healthcare provider or someone who regularly uses oxygen therapy, knowing where to turn for assistance is key.

When to Contact a Professional for Oxygen Tank Services

There are certain scenarios where reaching out to a professional is not just recommended, it’s necessary. Here’s when you should make the call:

- If you notice irregular tank behavior that’s not covered by standard troubleshooting.

- When servicing needs arise, such as refilling or routine maintenance checks.

- If you’re ever unsure about any aspect of pressure release, maintenance, or handling.

For instance, MasVida Health offers reliable and cost-effective oxygen rental and transfill services, ensuring that you have access to professional support when you need it. With their expertise, you can remove the guesswork and ensure your oxygen tanks are handled safely and efficiently.

Training and Certification for Handling Oxygen Tanks

Investing in training programs and obtaining certification can significantly enhance your ability to manage oxygen tanks safely. Here’s why it’s beneficial:

- Proper training equips you with the knowledge to prevent accidents and handle oxygen responsibly.

- Certification demonstrates your commitment to safety and can be a requirement in certain settings.

By seeking out these educational opportunities, you not only bolster your own skills but also contribute to a safer environment for everyone involved in oxygen therapy. Remember, informed handling is safe handling, and that’s a priority for everyone.

Frequently Asked Questions

Question 1:

What should you do if the oxygen tank’s pressure gauge is not working properly?

Answer:

Check for a replacement gauge or contact a professional to assess and repair the malfunctioning gauge.

Question 2:

Can you release pressure from an oxygen tank in a cold environment?

Answer:

Yes, but ensure the valve isn’t frozen and the tank is handled with care to prevent any temperature-related issues.

Question 3:

How do you know when an oxygen tank is empty and safe to remove from service?

Answer:

The pressure gauge will read zero PSI, indicating the tank is empty and can be safely removed.

Question 4:

What is the safest way to transport an oxygen tank after releasing pressure?

Answer:

Secure the tank in an upright position, close the valve, and ensure it’s not exposed to heat or direct sunlight during transport.

Question 5:

Is it necessary to have a fire extinguisher nearby when releasing pressure from an oxygen tank?

Answer:

Yes, having a fire extinguisher close by is a recommended safety precaution due to the increased fire risk in oxygen-rich environments.

Join healthcare’s ultimate resource for long-term care!

• Follow Us on Linkedin

• Join our weekly Newsletter

OneSource: Your Single Source for Same-day DME Delivery and Better Facility Hygiene

Better products. Better service. Better outcomes.

Partnering with one provider for your DME and facility hygiene services can result in reduced turnover, higher quality work, and healthier facilities.

Medical OxygenTherapy →

Negative Pressure (NPWT) →

Respiratory Therapy →

Durable Medical Equipment →